Chlorine trifluoride (ClF3) is a chemical compound that has garnered significant attention due to its unique properties and diverse applications across various industries. This colorless gas, which can also exist as a pale yellow liquid under certain conditions, is known for its highly reactive nature. Chlorine trifluoride is a powerful oxidizing agent, making it particularly valuable in processes that require vigorous chemical reactions.

Its ability to react with a wide range of materials, including metals and non-metals, positions it as a critical component in several industrial applications. The compound was first synthesized in the 1930s, and since then, its potential has been explored in various fields, including semiconductor manufacturing, nuclear power, aerospace, and chemical synthesis. As industries continue to evolve and seek more efficient and effective materials, chlorine trifluoride remains at the forefront of innovation.

Understanding its chemical properties, safety considerations, and industrial applications is essential for harnessing its capabilities while mitigating associated risks.

Key Takeaways

- Chlorine trifluoride is a highly reactive and hazardous chemical with unique properties and a complex molecular structure.

- It plays a critical role in semiconductor manufacturing, nuclear power, aerospace, and chemical synthesis industries.

- Strict safety protocols are essential due to its extreme toxicity and potential for violent reactions.

- Its applications include use as a rocket propellant, cleaning agent, and etching chemical in electronics.

- Ongoing research focuses on minimizing environmental impact and expanding industrial uses while ensuring regulatory compliance.

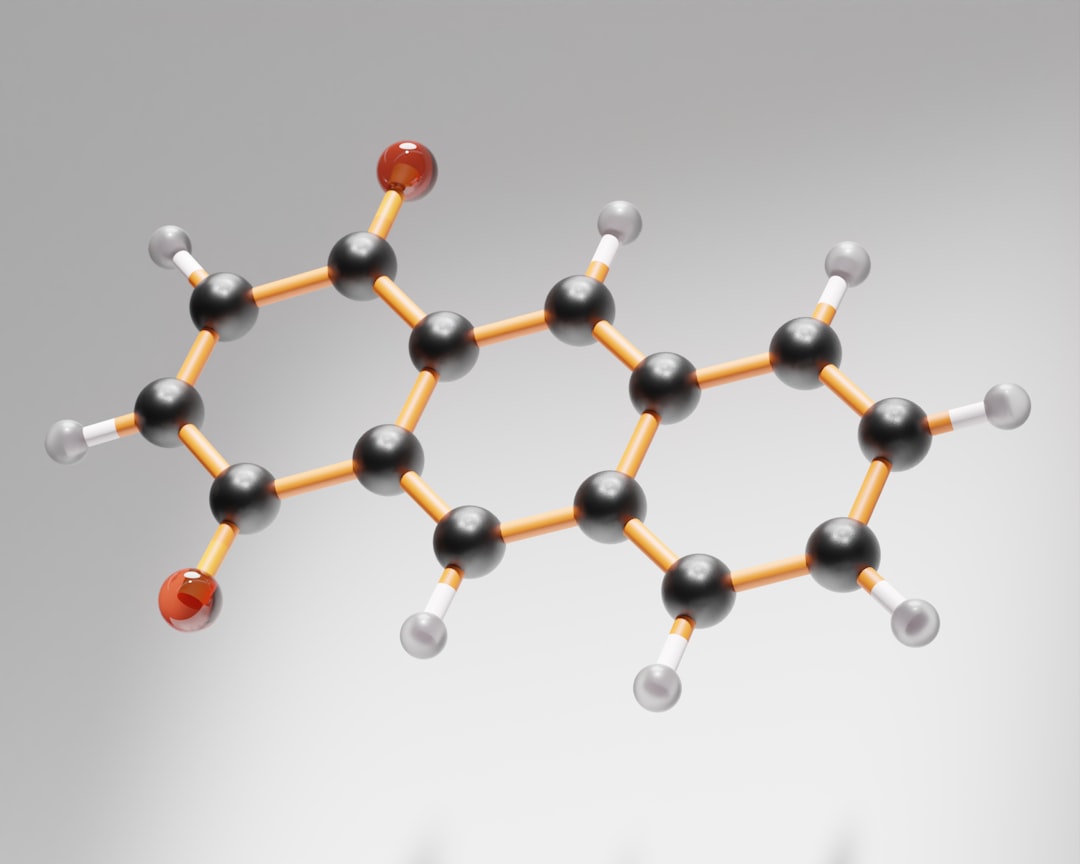

Chemical Properties and Structure of Chlorine Trifluoride

Chlorine trifluoride is characterized by its molecular structure, which consists of one chlorine atom bonded to three fluorine atoms. This arrangement results in a trigonal bipyramidal geometry, contributing to the compound’s unique reactivity. The bond angles between the fluorine atoms are approximately 109.5 degrees, which is typical for molecules with sp3 hybridization.

The electronegativity of fluorine makes the Cl-F bonds highly polar, leading to a significant dipole moment that enhances the compound’s oxidizing properties. In terms of chemical properties, chlorine trifluoride is notable for its ability to react violently with water, producing hydrochloric acid and hydrofluoric acid. This reaction exemplifies the compound’s aggressive nature and highlights the need for careful handling.

Additionally, ClF3 can react with organic materials and metals, often resulting in combustion or explosive reactions. Its high boiling point of 11 degrees Celsius and low freezing point of -76 degrees Celsius allow it to exist as a gas or liquid under various conditions, further expanding its utility in industrial applications.

Safety Considerations and Hazards of Chlorine Trifluoride

The highly reactive nature of chlorine trifluoride poses significant safety concerns that must be addressed in any industrial setting where it is used. Due to its corrosive properties, ClF3 can cause severe burns upon contact with skin or eyes. Inhalation of the gas can lead to respiratory distress and other serious health issues.

Therefore, stringent safety protocols are essential when handling this compound. Personal protective equipment (PPE), including gloves, goggles, and respiratory protection, is crucial to minimize exposure risks. Moreover, the potential for violent reactions with water and organic materials necessitates careful storage and transportation practices.

Chlorine trifluoride must be stored in specialized containers that can withstand its corrosive effects and prevent accidental release into the environment. Emergency response plans should also be in place to address potential leaks or spills, ensuring that personnel are trained to handle such incidents effectively. The hazards associated with chlorine trifluoride underscore the importance of rigorous safety measures in industries that utilize this compound.

Industrial Uses of Chlorine Trifluoride in the Semiconductor Industry

| Metric | Description | Value / Range | Unit | Notes |

|---|---|---|---|---|

| Purity Level | Purity of chlorine trifluoride used in semiconductor etching | 99.9 – 99.99 | % | High purity required to avoid contamination |

| Etch Rate | Rate at which chlorine trifluoride etches silicon wafers | 100 – 500 | nm/min | Depends on process parameters and wafer type |

| Operating Temperature | Temperature range for effective etching | 25 – 200 | °C | Varies with equipment and process design |

| Pressure Range | Chamber pressure during etching process | 0.1 – 10 | Torr | Low pressure to control reaction kinetics |

| Gas Flow Rate | Flow rate of chlorine trifluoride gas during processing | 50 – 500 | sccm (standard cubic centimeters per minute) | Optimized for uniform etching |

| Material Compatibility | Materials resistant to chlorine trifluoride corrosion | Nickel, Monel, Tantalum | N/A | Used for reactor and piping components |

| Safety Threshold | Maximum allowable exposure limit for workers | 0.1 | ppm (parts per million) | Strict monitoring required due to high toxicity |

| Typical Application | Primary use in semiconductor manufacturing | Silicon wafer cleaning and etching | N/A | Enables high precision microfabrication |

In the semiconductor industry, chlorine trifluoride plays a pivotal role as an etching agent during the fabrication of microelectronic devices. Its strong oxidizing properties enable it to effectively remove unwanted materials from silicon wafers, allowing for precise patterning and layering essential for modern electronics. The ability of ClF3 to etch silicon dioxide and other dielectric materials makes it an invaluable tool in the production of integrated circuits.

Furthermore, as technology advances and devices become smaller and more complex, the demand for efficient etching processes has increased. Chlorine trifluoride meets this demand by providing a fast and effective means of achieving high-resolution patterns on semiconductor substrates. Its compatibility with various materials used in semiconductor manufacturing further enhances its appeal, making it a preferred choice among manufacturers striving for precision and efficiency in their production processes.

Applications of Chlorine Trifluoride in the Nuclear Power Industry

Chlorine trifluoride also finds significant applications within the nuclear power industry, primarily as a fluorinating agent in the processing of nuclear fuels. Its ability to react with uranium and other actinides allows for the conversion of these materials into gaseous fluorides, which can then be further processed for use in nuclear reactors. This capability is particularly important for the development of advanced nuclear fuel cycles that aim to improve efficiency and reduce waste.

Additionally, ClF3 is utilized in the decontamination of nuclear facilities due to its strong oxidizing properties. It can effectively remove radioactive contaminants from surfaces and equipment, ensuring that facilities maintain safe operating conditions. The use of chlorine trifluoride in these applications highlights its versatility and importance in supporting the nuclear power sector’s goals of safety and sustainability.

Chlorine Trifluoride in the Aerospace Industry: Rocket Propellant and Cleaning Agent

In the aerospace industry, chlorine trifluoride serves dual purposes as both a rocket propellant and a cleaning agent. As a propellant, ClF3 is valued for its high energy content and efficiency when combined with hydrogen or other fuels. Its ability to produce thrust through rapid combustion makes it an attractive option for propulsion systems in space exploration missions.

The high performance characteristics of chlorine trifluoride contribute to advancements in rocket technology, enabling more ambitious missions beyond Earth’s atmosphere. Moreover, chlorine trifluoride is employed as a cleaning agent for aerospace components due to its effectiveness in removing contaminants such as oils, greases, and other residues that can compromise performance. The compound’s strong oxidizing properties allow it to break down complex organic materials quickly and efficiently.

This application is particularly critical in maintaining the integrity of sensitive aerospace systems where even minor contaminants can lead to significant operational issues.

Role of Chlorine Trifluoride in the Chemical Synthesis Industry

Chlorine trifluoride plays a crucial role in the chemical synthesis industry as a versatile reagent for various chemical reactions. Its strong oxidizing capabilities make it an effective agent for synthesizing fluorinated compounds, which are increasingly important in pharmaceuticals, agrochemicals, and specialty chemicals. The ability to introduce fluorine into organic molecules can enhance their biological activity and stability, making ClF3 an essential tool for chemists seeking to develop new compounds with desirable properties.

Additionally, chlorine trifluoride is utilized in polymer chemistry for the production of fluoropolymers, which possess unique characteristics such as high thermal stability and chemical resistance. These polymers find applications in coatings, electrical insulation, and other specialized materials that require durability under extreme conditions. The versatility of chlorine trifluoride as a reagent underscores its significance in advancing chemical synthesis techniques across various sectors.

Chlorine Trifluoride as a Cleaning and Etching Agent in the Electronics Industry

In the electronics industry, chlorine trifluoride is employed as both a cleaning and etching agent due to its effectiveness in removing contaminants from electronic components and substrates. The precision required in electronics manufacturing necessitates the use of agents that can clean surfaces without causing damage or altering material properties. ClF3 meets these criteria by providing a thorough cleaning process that eliminates residues while preserving the integrity of sensitive components.

As an etching agent, chlorine trifluoride is particularly valuable for patterning thin films used in electronic devices. Its ability to selectively etch specific materials allows manufacturers to create intricate designs essential for modern electronics. The combination of cleaning and etching capabilities makes chlorine trifluoride an indispensable resource for electronics manufacturers striving for high-quality production standards.

Environmental Impact and Regulations Surrounding the Use of Chlorine Trifluoride

Despite its numerous industrial applications, chlorine trifluoride raises environmental concerns due to its potential impact on air quality and human health. As a potent greenhouse gas with a global warming potential significantly higher than carbon dioxide, ClF3 contributes to climate change when released into the atmosphere. Consequently, regulatory agencies have established guidelines governing its use and emissions to mitigate environmental risks associated with this compound.

Industries utilizing chlorine trifluoride must adhere to strict regulations regarding storage, handling, and disposal practices to minimize environmental impact. Efforts are underway to develop alternative processes that reduce reliance on ClF3 while maintaining efficiency in industrial applications. The ongoing dialogue surrounding environmental sustainability emphasizes the need for responsible management of chlorine trifluoride within various sectors.

Future Trends and Developments in the Industrial Applications of Chlorine Trifluoride

Looking ahead, the future of chlorine trifluoride in industrial applications appears promising as research continues to explore innovative uses for this versatile compound. Advances in technology may lead to more efficient methods of utilizing ClF3 while minimizing environmental impact. For instance, ongoing studies aim to develop closed-loop systems that capture emissions during production processes, reducing overall greenhouse gas contributions.

Moreover, as industries increasingly prioritize sustainability and eco-friendly practices, there may be a shift towards finding alternatives to chlorine trifluoride that offer similar benefits without posing significant environmental risks.

The Importance of Chlorine Trifluoride in Various Industrial Sectors

In conclusion, chlorine trifluoride stands out as a critical compound with diverse applications across multiple industrial sectors. From semiconductor manufacturing to aerospace propulsion systems, its unique chemical properties enable innovative solutions that drive technological advancements. However, alongside its benefits come significant safety considerations and environmental challenges that necessitate responsible management practices.

As industries continue to evolve and seek more efficient materials, understanding the role of chlorine trifluoride will be essential for harnessing its capabilities while addressing associated risks. The ongoing exploration of new applications and sustainable practices surrounding ClF3 underscores its importance as a versatile reagent in modern industrial chemistry. Ultimately, chlorine trifluoride’s contributions will play a vital role in shaping the future landscape of various industries while balancing innovation with safety and environmental stewardship.

Chlorine trifluoride (ClF3) is a highly reactive chemical that has found various industrial applications, particularly in the field of semiconductor manufacturing and as a fluorinating agent. For a deeper understanding of its properties and uses, you can refer to a related article that discusses the industrial applications of chlorine trifluoride in detail. To explore this topic further, visit this article.

WATCH THIS 🔒 The 5 Materials So Dangerous They’re Locked in Nuclear Bunkers

FAQs

What is chlorine trifluoride?

Chlorine trifluoride (ClF3) is a highly reactive and toxic chemical compound composed of one chlorine atom and three fluorine atoms. It is a colorless, poisonous, and corrosive gas or pale greenish-yellow liquid under certain conditions.

What are the primary industrial uses of chlorine trifluoride?

Chlorine trifluoride is primarily used as a fluorinating agent in the semiconductor industry, for cleaning chemical vapor deposition (CVD) chambers, and in the production of uranium hexafluoride for nuclear fuel processing. It is also used in specialized applications requiring strong oxidizers and fluorinating agents.

Why is chlorine trifluoride used in semiconductor manufacturing?

In semiconductor manufacturing, chlorine trifluoride is used to clean chemical vapor deposition chambers because it can remove silicon and other deposits effectively without damaging the equipment. Its strong fluorinating properties make it ideal for this purpose.

Is chlorine trifluoride safe to handle in industrial settings?

Chlorine trifluoride is extremely hazardous due to its high reactivity, toxicity, and corrosiveness. It can ignite many materials on contact and cause severe chemical burns. Therefore, it requires specialized handling procedures, protective equipment, and strict safety protocols in industrial environments.

How is chlorine trifluoride stored and transported?

Chlorine trifluoride is stored in specially designed containers made of materials resistant to its corrosive nature, such as certain nickel alloys. Transportation follows stringent regulations to prevent leaks, exposure, and accidental reactions, including the use of secure, labeled containers and controlled environments.

What precautions are necessary when using chlorine trifluoride industrially?

Precautions include using appropriate personal protective equipment (PPE), ensuring proper ventilation, employing remote handling systems, maintaining strict control over storage and transfer processes, and having emergency response plans in place to address potential leaks or fires.

Can chlorine trifluoride be used as a weapon?

Due to its extreme reactivity and toxicity, chlorine trifluoride has been studied for potential military applications as an incendiary or chemical agent. However, its use as a weapon is highly restricted and controlled under international laws and treaties.

What environmental impacts does chlorine trifluoride have?

If released, chlorine trifluoride can cause severe environmental damage due to its corrosive and reactive nature. It can contaminate air and water, harm living organisms, and react violently with organic materials. Proper containment and disposal are essential to minimize environmental risks.

How is chlorine trifluoride produced industrially?

Chlorine trifluoride is typically produced by the direct reaction of chlorine gas with fluorine gas under controlled conditions. The process requires careful temperature and pressure management to ensure safety and product purity.

Are there alternatives to chlorine trifluoride for industrial applications?

Yes, alternatives such as other fluorinating agents or cleaning chemicals may be used depending on the specific application. However, chlorine trifluoride’s unique properties often make it the preferred choice for certain high-performance industrial processes.